At Beta Shim, we specialize in delivering precision manufacturing solutions tailored to the most demanding industries, including aerospace, defense, and commercial sectors. With decades of experience and a commitment to cutting-edge technology, we offer a full suite of services designed to take your project from concept to completion with speed, accuracy, and reliability.

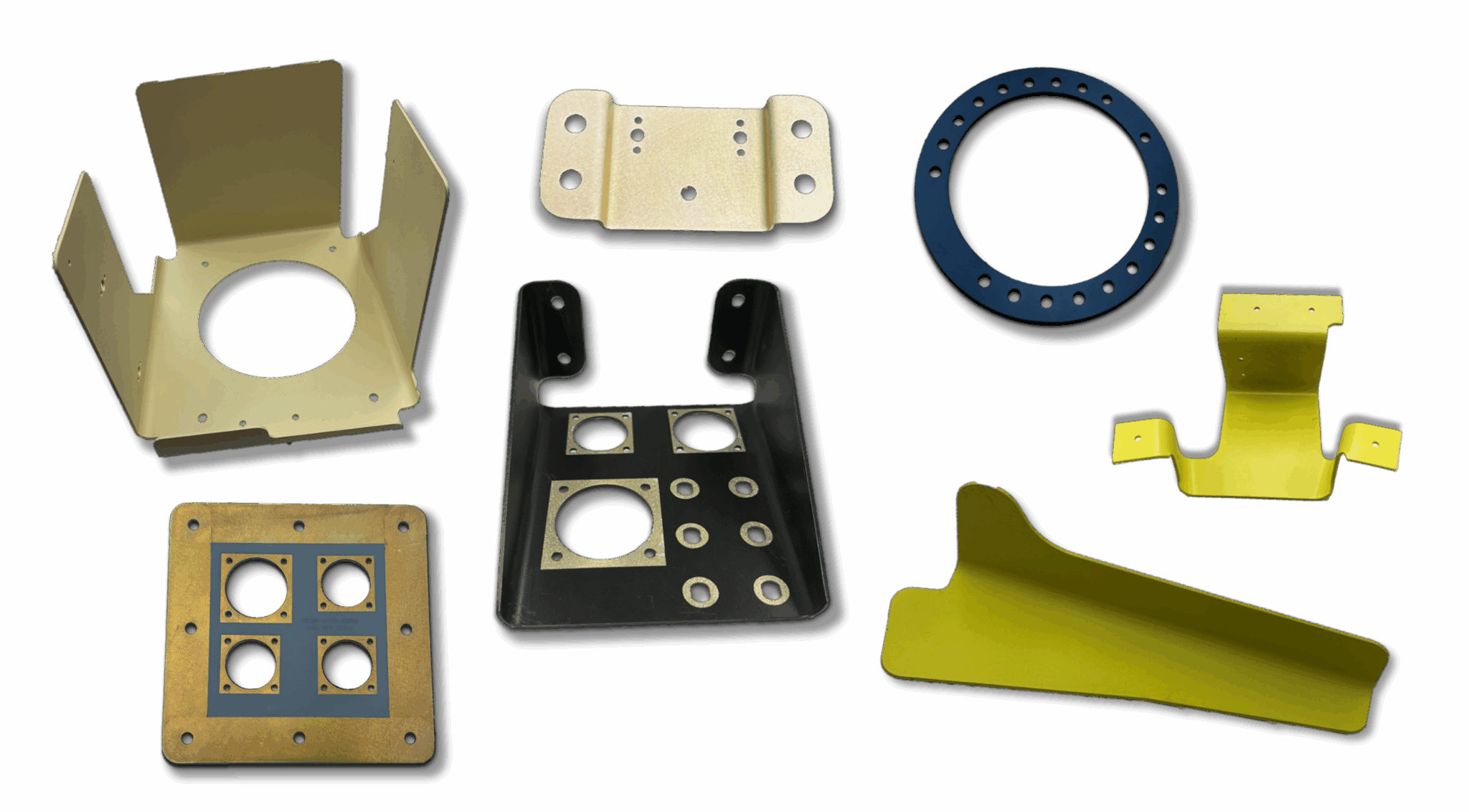

With over 40 years of experience, our team expertly handles everything from delicate materials to heavy-duty metals. Our stamping and forming capabilities include presses ranging from 20 to 80+ tons and CNC turret presses, enabling us to meet rigorous tolerances and complex geometries—perfect for aerospace and custom applications.

To complete the manufacturing lifecycle, we provide in-house assembly and kitting services. Our team can handle ground support tooling, pneumatic crimping and riveting, bearing and bushing press fits, and more. We also supply complete kitting solutions—delivering rivets, sub-assemblies, and components ready for immediate integration into your production line.

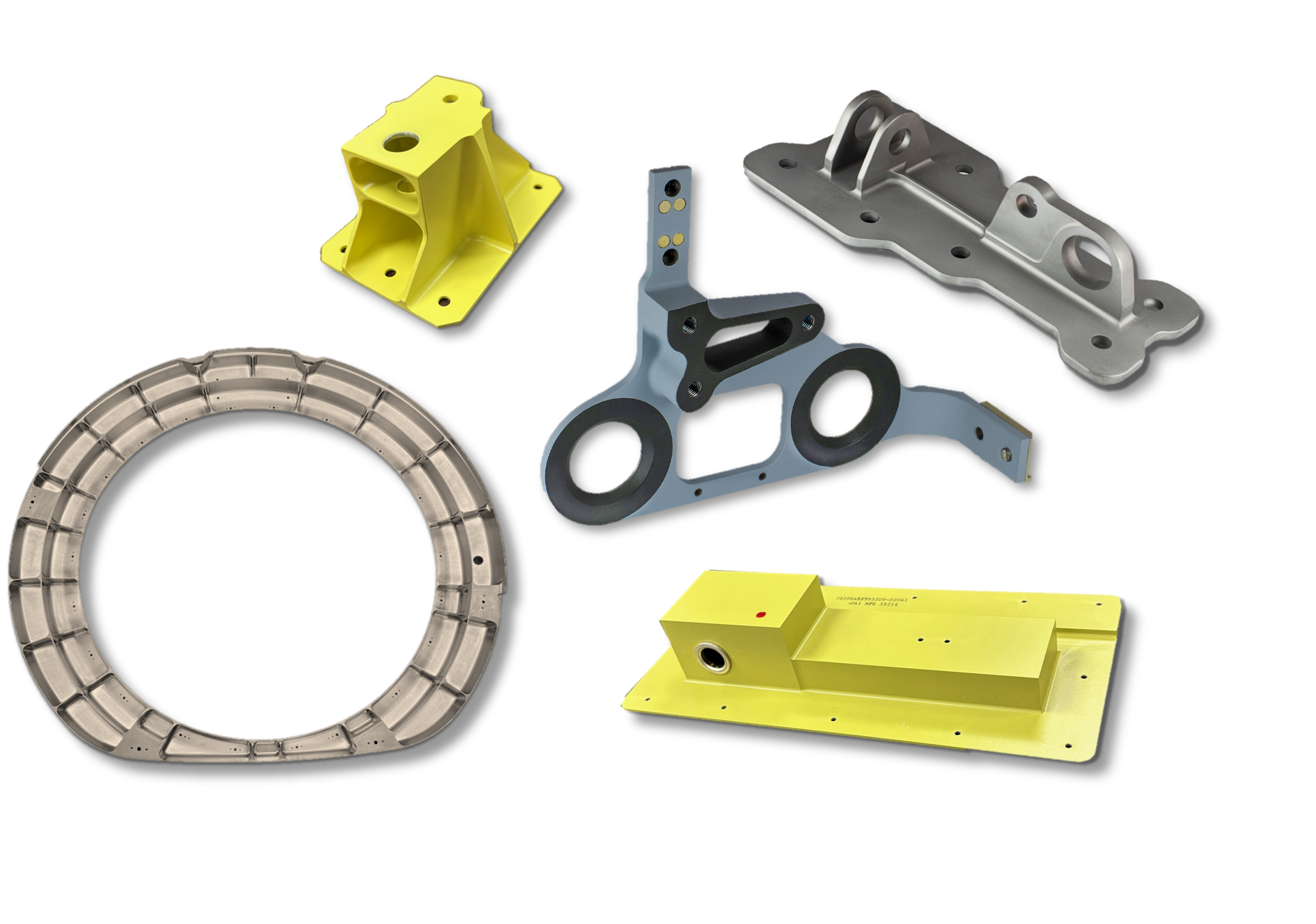

Our machining centers—including Mazak J500 and Fadal/MAG systems—are equipped to handle everything from prototyping to high-volume runs. Our expert programmers ensure seamless interoperability across platforms like AutoCAD, Mastercam, AP100US, SolidWorks, and CATIA for efficient, high-precision output.

As one of the first shops in the region to implement CNC turning, we operate advanced Mazak CNC lathes capable of turning diameters up to 3 inches. Supported by industry-standard CAD/CAM software like AutoCAD, Mastercam, SolidWorks, and CATIA, we ensure precision, repeatability, and quality in every component we produce.

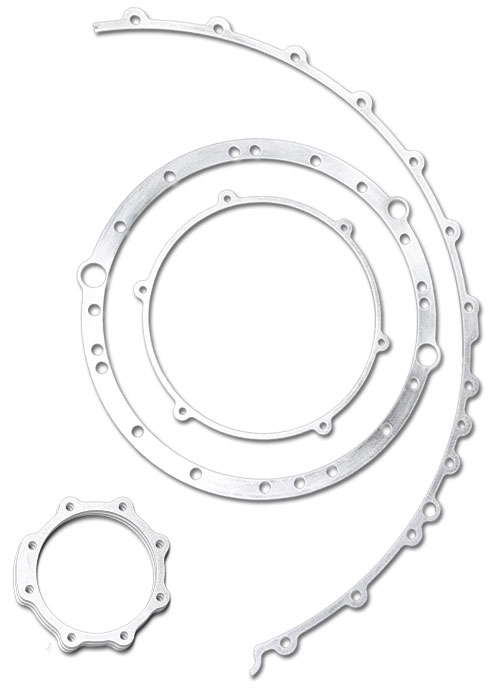

We manufacture high-performance laminated metal sheets by bonding ultra-thin precision foils into custom-thickness sheets. With sizes up to 48 inches long and 24 inches wide, these peelable laminates allow for easy, on-the-fly adjustments during assembly—offering the flexibility of solid shims with none of the machining hassle.