With over 75 years of experience, we specialize in delivering high quality precision parts. We remain committed to continually improving our quality management system and enhancing customer satisfaction. We use state of the art inspection equipment to meet our customers expectations by conforming to the ISO 9001 and AS9100 Quality Management Standards.

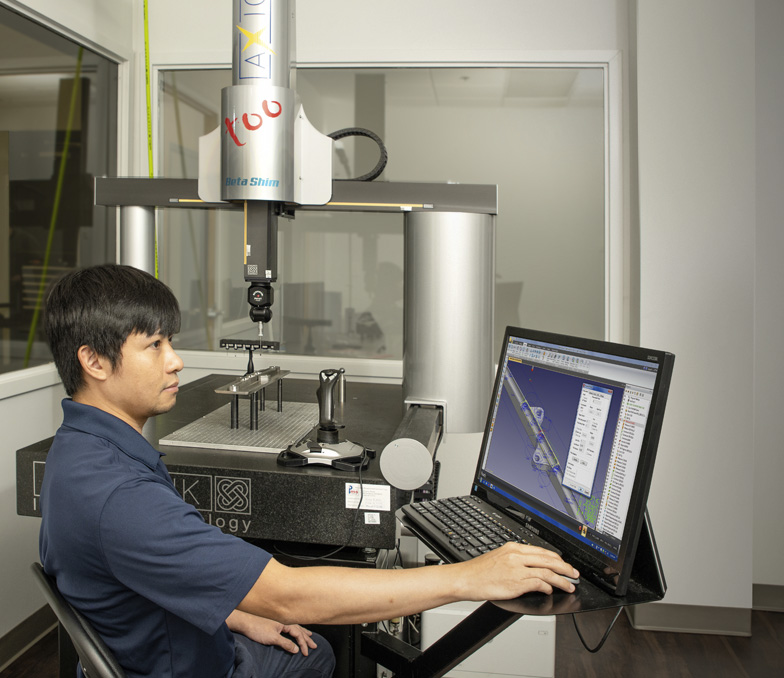

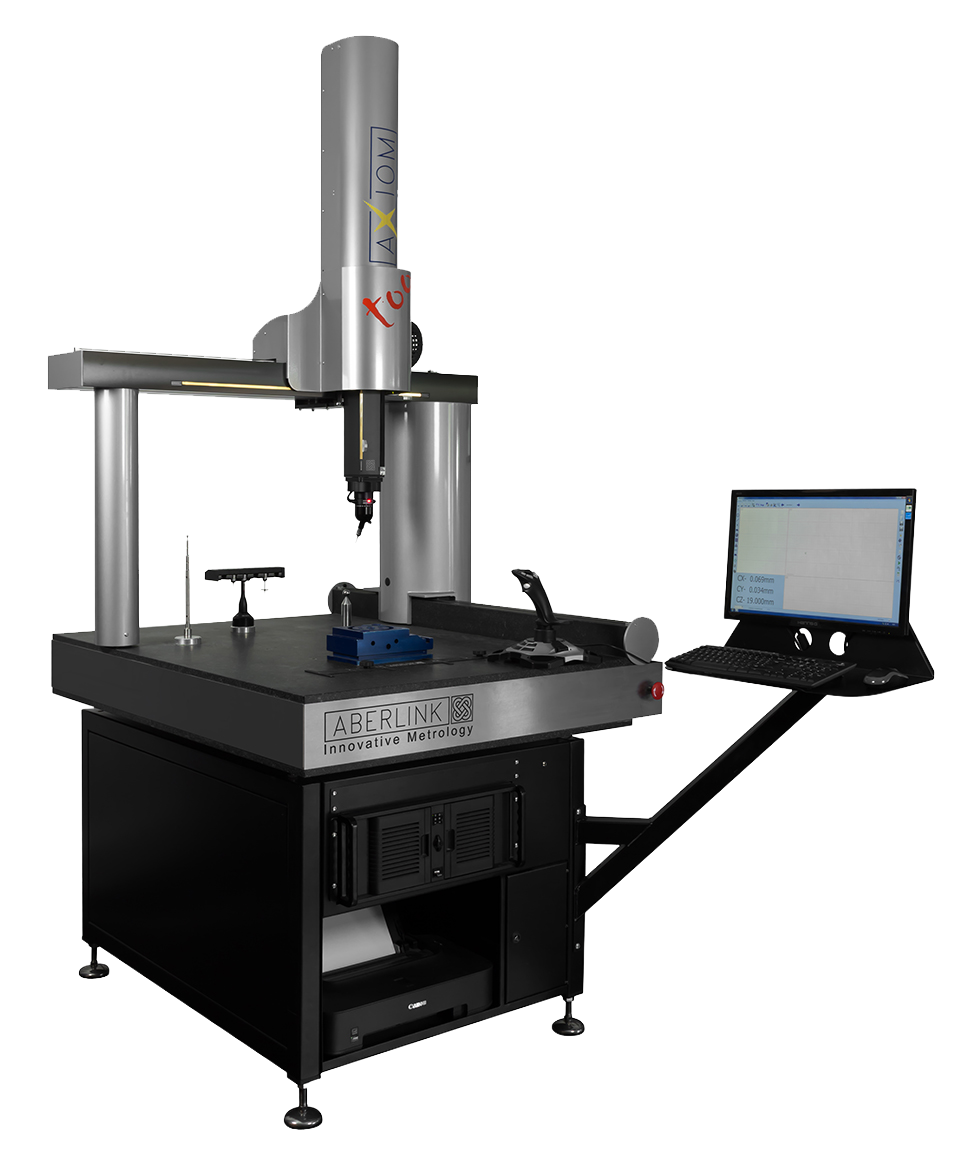

The Axiom too CMM has 640 x 500 (mm – axis travel), with TP20 modules. It is equipped with a Renishaw PH10T motorized head for very fast probe alignment changes.

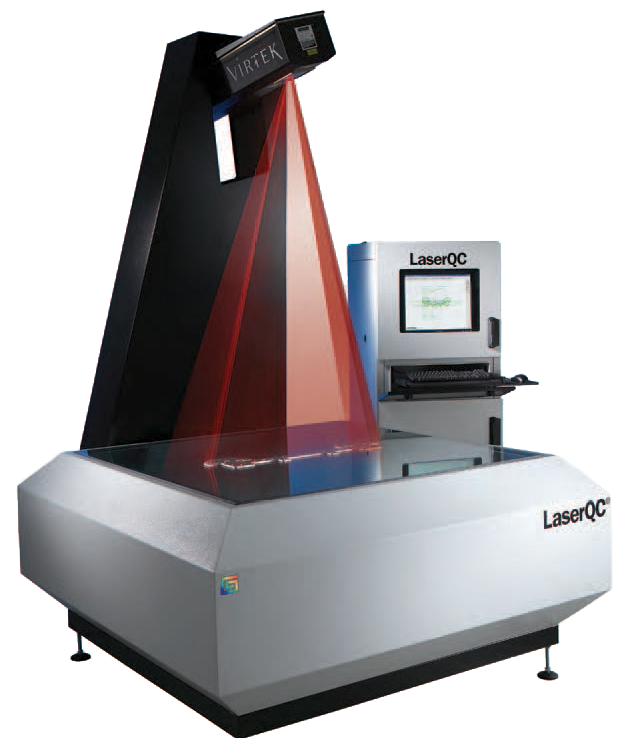

The Virtek Laser QC can capture more than 500 data points per second by using lasers to measure the accuracy of two-dimensional parts to tolerances within 0.0002 inches.

The Keyence IM-7500 can measure up to 99 dimensions on up to 100 parts with the push of a button. Minimal set up and automatic focal adjustments makes this piece of equipment extremely efficient.

The FARO Quantum S Arm is a coordinate measuring machine used for verifying products through 3D inspections, dimensional analysis, CAD comparison, tool certifications, reverse engineering, and more.