While Beta Shim’s manufacturing capabilities have greatly expanded over the years, our expertise and experience in the field of metal stamping and punching is unparalleled. In addition to the newer CNC methods of metal stamping, Beta Shim maintains a large staff of experienced engineers and press operators to ensure any custom job can be handled by our shop. CNC methods are great for high efficiency with either large or small quantity runs. Our engineers, press operators, and tooling experts have over two decades of experience manufacturing to the highly demanding standard of the Aerospace industry and beyond. Rest assured your parts are manufactured to the highest standards without exception.

We maintain a variety of traditional presses ranging in size from 20 tons to 80+ tons. In addition to our conventional presses, we have added two Amada CNC turret presses. This allows us the precision for precious metal work and tight tolerances, the brute strength needed for extremely thick or resistant materials, and the rapid repeatability for maximum efficiency.

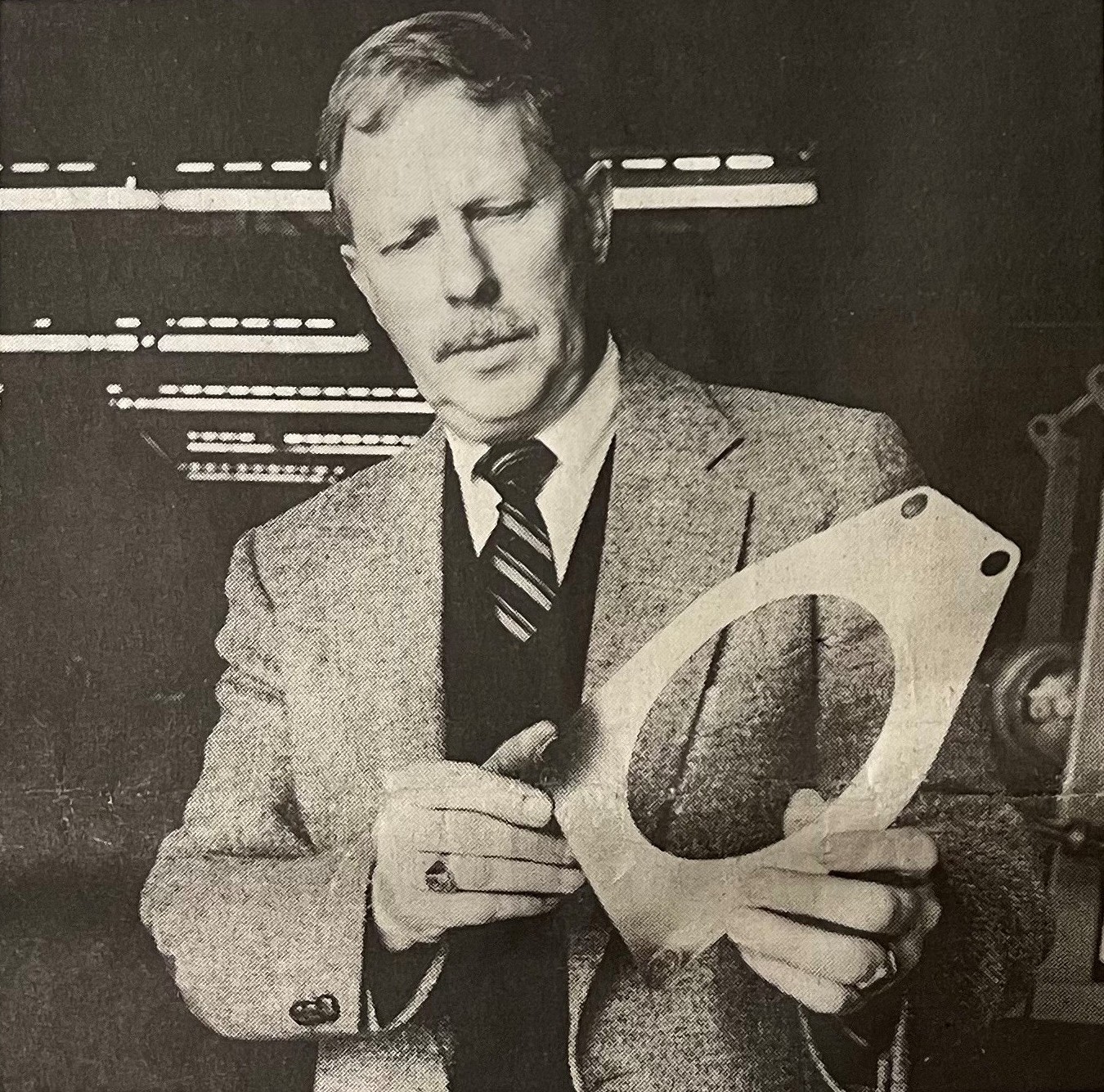

Beta Shim is an award-winning manufacturer serving the aerospace industry. We take great pride in the quality parts we produce and we go above and beyond to provide our customers with great service.

We are honored to be recognized by our customers and would like to share in some of our recent achievements: