At Beta Shim, metal stamping and punching aren’t just part of what we do—they’re at the core of our legacy. While our manufacturing capabilities have expanded significantly over the years, our expertise in stamping and punching remains unmatched.

We offer both traditional and CNC-based metal stamping, allowing us to accommodate everything from high-efficiency production runs to complex custom jobs—all built to the exacting standards of the aerospace industry and beyond.

Our team includes seasoned engineers, press operators, and tooling experts, many with over 20 years of experience. They ensure that every part is manufactured to the highest standards—without exception.

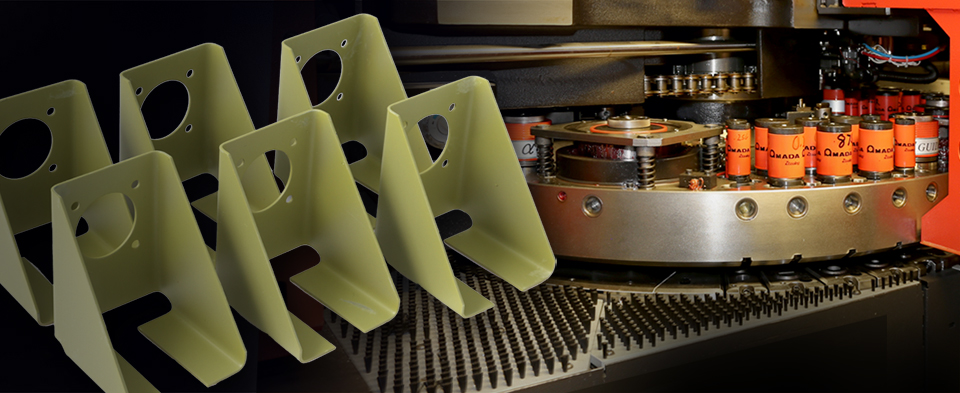

We operate a versatile lineup of equipment, including:

Traditional mechanical presses ranging from 20 to 80+ tons

Two Amada CNC turret presses for tight-tolerance work, precious metals, and high-speed production

Our capabilities give us:

The precision needed for fine, detailed stamping

The strength to handle thick or resistant materials

The speed and repeatability to ensure production efficiency

No matter the size, shape, or material, Beta Shim is fully equipped to meet your metal stamping and punching needs—with craftsmanship, consistency, and confidence.

Need metal parts manufactured to aerospace-grade standards? Contact us.